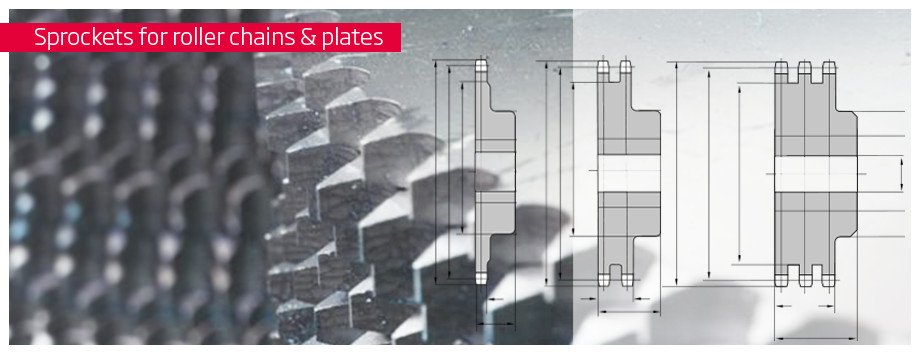

Sprockets and Plate Wheels

We really sink our teeth into it.

Materials and build quality of sprockets are critical to the life of any chain system. At KÖBO, our production is known for using the highest of standards for our manufacturing processes. We use our highest grade of KÖBO power spectrum on all our sprockets. And depending on specifications and application, we utilize induction hardened teeth as well.

Realize what possible is.

Using our large production facilities we can manufacture sprockets and sprocket plates in nearly any exacting variation up to a diameter of 1700mm. We feel just as at home working with specialized sprockets as we do with single, dual and triple roller chains and sprockets. If a customer needs it, we can make it. We create customized solutions and materials upon request. Just look at our corrosion-resistant and split designs as an example.

We manufacture our sprockets with these features:

- One-sided hub, symmetric or asymmetric

- Welded hub, welded or manufactured

- Passfedernut – key grooved

- Threaded for screwholes

- Debris channeling/grooves

- Enhanced joint play

- Shear pins

- Interchangeable tooth segmenting

- Pre-gearing

- Hardened teeth

- Tooth shaping according to DIN, or special forms

- Noise attenuation